Product Center

Vibrating Feeder

Circular Vibrating Screen

Linear Vibrating Screen

Spiral Screen

XSD Sand Washer

XL Sand Washer

XT Drum Stone Washer

Belt Conveyor

Have question? Sales representatives

are available for live chat now.

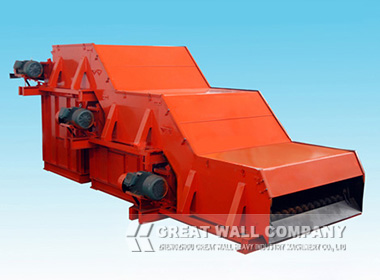

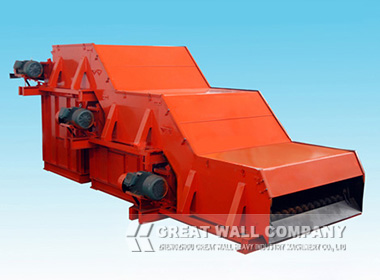

Spiral Screen

SL-U2 series of spiral screen is mainly used in industry of coal dressing, electricity generation, cement, oil refining, fertilizer, etc. Its function is to screen and separate dry&wet coal, not only to have good performance in screening dry material , but also to avoid sieve hole blocked in screening wet material especially fine size with moisture. It has high rate of screening which is new equipment in sieving wet, stick, fine coal.

0086-371-63769782

sales@greatwallcrusher.com

- Usage and Application

- Working Principle

- Features

- Main Specifications

Screw shaft has a high rotation speed, material moving speed on screen can be 0.5-1 m/s, so this equipment has big capacity. Meanwhile, when block material slides on screw surface, it can wash out wet powder which is stick to its surface. That means no matter how much moisture material contains, after sieved, the screen surface would always be clean, screen holes will also not be blocked. When screening, material would always be on different radial location of screw shaft, when screw shaft rotates, because of different linear speed of material, it can make material screened loosely, also after several times sieve, material rolls and falls through which makes it has very high efficiency of screening. This working principle is definitely different from vibrating screen equipment which has controlled screen area for decades of years. Vibrating screen tosses material by vibration,but when occurring wet and stick material, powder would easily form a layer and block screen holes which would make 100% sieve much difficult. Especially for 8,10,13mm screen holes, the machine cannot even have screen classification. Besides, the moving power also comes from material itself when the screen inclines, material would be moved slowly and passively, by this way, working efficiency is surely very low. It is called passive screen. But for spiral sieve, it pushes material to move forward by rotation of screw, screen hole is dynamic which can make screen through rate in a high level, it is called positive screen. What’s more, adjacent two screws which forms screen holes have contrary linear direction when forming holes’ projection direction. Material rolls and moves by a pair of couple function, not by function of squeezing, so there will not be new crushing situation.

① High rate for through screen;

② Wet stick coal will not block screen hole;

③ No vibration, low noise;

④ Fast moving speed,big capacity(2 times bigger than vibrating screen);

⑤ Sieve surface is sturdy and durable;

⑥ No new crushing;

⑦ When used in electricity station, full closed product can protect better environment of coal production system ;

0-100mm standard series of screen technical feature

| Item |

Standard series |

Area (M2) |

Capacity (t/h) |

Efficiency (%) |

Feeding Size (mm) |

Feeding Moisture (%) |

Inclination angle of screen (Degree) |

Units (pcs) |

Dimension L×W×H (m) |

Weight (t) |

Motor Power (kW) |

| 1 | SL—U2100/2.5—C | 15 | ≤2000 | 90 | 0~500 | NoLimitation | 0 | 4 | 7.6×3.5×3 | 24.4 | 11×8 |

| 2 | SL—U2100/2.5—B | 11.25 | ≤1600 | 90 | 3 | 5.8×3.5×2.3 | 18.3 | 11×6 | |||

| 3 | SL—U2100/2—B | 9 | ≤1200 | 90 | 3 | 5.8×3×2.3 | 16.8 | 7.5×6 | |||

| 4 | SL—U2100/2—A | 6 | ≤800 | 85 | 2 | 4×3×1.6 | 11.2 | 7.5×4 | |||

| 5 | SL—U2100/1.5—B | 6.75 | ≤700 | 90 | 3 | 5.8×2.5×2.3 | 14.4 | 5.5×6 | |||

| 6 | SL—U2100/1.5—A | 4.5 | ≤500 | 85 | 2 | 4×2.5×1.6 | 9.6 | 5.5×4 |

0-80mm standard series of screen technical feature

| Item |

Standard series |

Area (M2) |

Capacity (t/h) |

Efficiency (%) |

Feeding Size (mm) |

Feeding Moisture (%) |

Inclination angle of screen (Degree) |

Units (pcs) |

Dimension L×W×H (m) |

Weight (t) |

Motor Power (kW) |

| 1 | SL—U280/2.5—C | 15 | ≤1500 | 90 | 0~500 | No limitation | 0 | 4 | 7.6×3.5×3 | 24.4 | 11×8 |

| 2 | SL—U280/2.5—B | 11.25 | ≤1200 | 90 | 3 | 5.8×3.5×2.3 | 18.3 | 11×6 | |||

| 3 | SL—U280/2—B | 9 | ≤1000 | 90 | 3 | 5.8×3×2.3 | 16.8 | 7.5×6 | |||

| 4 | SL—U280/2—A | 6 | ≤700 | 85 | 2 | 4×3×1.6 | 11.2 | 7.5×4 | |||

| 5 | SL—U280/1.5—B | 6.75 | ≤600 | 90 | 3 | 5.8×2.5×2.3 | 14.4 | 5.5×6 | |||

| 6 | SL—U280/1.5—A | 4.5 | ≤400 | 85 | 2 | 4×2.5×1.6 | 9.6 | 5.5×4 |

0-50mm standard series of screen technical feature

| Item |

Standard series |

Area (M2) |

Capacity (t/h) |

Efficiency (%) |

Feeding Size (mm) |

Feeding Moisture (%) |

Inclination angle of screen (Degree) |

Units (pcs) |

Dimension L×W×H (m) |

Weight (t) |

Motor Power (kW) |

| 1 | SL—U250/2.5—C | 15 | ≤1300 | 90 | 0~500 | No limitation | 0 | 4 | 7.6×3.5×3 | 22 | 11×8 |

| 2 | SL—U250/2—C | 12 | ≤1000 | 90 | 4 | 7.6×3×3 | 18 | 7.5×8 | |||

| 3 | SL—U250/2—B | 9 | ≤700 | 90 | 3 | 5.8×3×2.3 | 13.5 | 7.5×6 | |||

| 4 | SL—U250/2—A | 6 | ≤500 | 85 | 2 | 4×3×1.6 | 9 | 7.5×4 | |||

| 5 | SL—U250/1.5—B | 6.75 | ≤400 | 90 | 3 | 5.8×2.5×2.3 | 10.8 | 5.5×6 | |||

| 6 | SL—U250/1.5—A | 4.5 | ≤300 | 85 | 2 | 4×2.5×1.6 | 7.2 | 5.5×4 |

0-40mm standard series of screen technical feature

| Item |

Standard series |

Area (M2) |

Capacity (t/h) |

Efficiency (%) |

Feeding Size (mm) |

Feeding Moisture (%) |

Inclination angle of screen (Degree) |

Units (pcs) |

Dimension L×W×H (m) |

Weight (t) |

Motor Power (kW) |

| 1 | SL—U240/2.5—C | 15 | ≤1100 | 90 | 0~500 | No limitation | 0 | 4 | 7.6×3.5×3 | 22 | 11×8 |

| 2 | SL—U240/2.5—B | 11.25 | ≤900 | 85 | 3 | 5.8×3.5×2.3 | 16.5 | 11×6 | |||

| 3 | SL—U240/2—C | 12 | ≤800 | 90 | 4 | 7.6×3×2.3 | 18 | 7.5×8 | |||

| 4 | SL—U240/2—B | 9 | ≤600 | 90 | 3 | 5.8×3×2.3 | 13.5 | 7.5×6 | |||

| 5 | SL—U240/2—A | 6 | ≤400 | 85 | 2 | 4×3×1.6 | 9 | 7.5×4 | |||

| 6 | SL—U240/1.5—B | 6.75 | ≤300 | 90 | 3 | 5.8×2.5×2.3 | 10.8 | 5.5×6 | |||

| 7 | SL—U240/1.5—A | 4.5 | ≤200 | 85 | 2 | 4×2.5×1.6 | 7.2 | 5.5×4 |

0-25mm standard series of screen technical feature

| Item | Standard series |

Area (M2) |

Capacity (t/h) |

Efficiency (%) |

Feeding Size (mm) |

Feeding Moisture (%) |

Inclination angle of screen (Degree) |

Units (pcs) |

Dimension L×W×H (m) |

Weight (t) |

Motor Power (kW) |

| 1 | SL—U225/2.5—C | 15 | ≤800 | 90 | 0~500 | No limitation | 0 | 4 | 7.6×3.5×3 | 22 | 11×8 |

| 2 | SL—U225/2.5—B | 11.25 | ≤700 | 85 | 3 | 5.8×3.5×2.3 | 16.5 | 11×6 | |||

| 3 | SL—U225/2—C | 12 | ≤600 | 90 | 4 | 7.6×3×3 | 18 | 7.5×8 | |||

| 4 | SL—U225/2—B | 9 | ≤450 | 90 | 3 | 5.8×3×2.3 | 13.5 | 7.5×6 | |||

| 5 | SL—U225/2—A | 6 | ≤350 | 85 | 2 | 4×3×1.6 | 9 | 7.5×4 | |||

| 6 | SL—U225/1.5—B | 6.75 | ≤300 | 90 | 3 | 5.8×2.5×2.3 | 10.8 | 5.5×6 | |||

| 7 | SL—U225/1.5—A | 4.5 | ≤200 | 85 | 2 | 4×2.5×1.6 | 7.2 | 5.5×4 |

0-20mm standard series of screen technical feature

| Item | Standard series |

Area (M2) |

Capacity (t/h) |

Efficiency (%) |

Feeding Size (mm) |

Feeding Moisture (%) |

Inclination angle of screen (Degree) |

Units (pcs) |

Dimension L×W×H (m) |

Weight (t) |

Motor Power (kW) |

| 1 | SL—U220/2.5—C | 15 | 500 | 90 | 0~200 | >8 | 0 | 4 | 7.6×3.5×3 | 22 | 11×8 |

| 600 | <8 | ||||||||||

| 2 | SL—U220/2.5—B | 11.25 | 400 | 85 | >8 | 3 | 5.8×3.5×2.3 | 16.5 | 11×6 | ||

| 500 | <8 | ||||||||||

| 3 | SL—U220/2—C | 12 | 350 | 90 | >8 | 4 | 7.6×3×2.3 | 18 | 7.5×8 | ||

| 450 | <8 | ||||||||||

| 4 | SL—U220/2—B | 9 | 300 | 90 | >8 | 3 | 5.8×3×2.3 | 13.5 | 7.5×6 | ||

| 400 | <8 | ||||||||||

| 5 | SL—U220/2—A | 6 | 250 | 80 | >8 | 2 | 4×3×1.6 | 9 | 7.5×4 | ||

| 300 | <8 | ||||||||||

| 6 | SL—U220/1.5—B | 6.75 | 200 | 90 | >8 | 3 | 5.8×2.5×2.3 | 10.8 | 5.5×6 | ||

| 250 | <8 | ||||||||||

| 7 | SL—U220/1.5—A | 4.5 | 150 | 80 | >8 | 2 | 4×2.5×1.6 | 7.2 | 5.5×4 |

0-13mm standard series of screen technical feature

| Item | Standard series |

Area (M2) |

Capacity (t/h) |

Efficiency (%) |

Feeding Size (mm) |

Feeding Moisture (%) |

Inclination angle of screen (Degree) |

Units (pcs) |

Dimension L×W×H (m) |

Weight (t) |

Motor Power (kW) |

| 1 | SL—U213/2.5—C | 15 | 400 | 90 | 0~200 | >8 | 0 | 4 | 7.6×3.5×3 | 22 | 11×8 |

| 450 | <8 | ||||||||||

| 2 | SL—U213/2.5—B | 11.25 | 350 | 90 | >8 | 3 | 5.8×3.5×2.3 | 16.5 | 11×6 | ||

| 400 | <8 | ||||||||||

| 3 | SL—U213/2—C | 12 | 300 | 90 | >8 | 4 | 7.6×3×3 | 18 | 7.5×8 | ||

| 350 | <8 | ||||||||||

| 4 | SL—U213/2—B | 9 | 250 | 90 | >8 | 3 | 5.8×3×2.3 | 13.5 | 7.5×6 | ||

| 300 | <8 | ||||||||||

| 5 | SL—U213/2—A | 6 | 150 | 85 | >8 | 2 | 4×3×1.6 | 9 | 7.5×4 | ||

| 180 | <8 | ||||||||||

| 6 | SL—U213/1.5—C | 9 | 200 | 90 | >8 | 4 | 7.6×2.5×3 | 14.4 | 5.5×8 | ||

| 250 | <8 | ||||||||||

| 7 | SL—U213/1.5—B | 6.75 | 120 | 90 | >8 | 3 | 5.8×2.5×2.3 | 10.8 | 5.5×6 | ||

| 150 | <8 | ||||||||||

| 8 | SL—U213/1.5—A | 4.5 | 100 | 85 | >8 | 2 | 4×2.5×1.6 | 7.2 | 5.5×4 |

0-10mm standard series of screen technical feature

| Item | Standard series |

Area (M2) |

Capacity (t/h) |

Efficiency (%) |

Feeding Size (mm) |

Feeding Moisture (%) |

Inclination angle of screen (Degree) |

Units (pcs) |

Dimension L×W×H (m) |

Weight (t) |

Motor Power (kW) |

| 1 | SL—U210/2.5—C | 15 | 300 | 90 | 0~200 | >8 | 0 | 4 | 7.6×3.5×3 | 22 | 11×8 |

| 350 | <8 | ||||||||||

| 2 | SL—U210/2.5—B | 11.25 | 250 | 90 | >8 | 3 | 5.8×3.5×2.3 | 16.5 | 11×6 | ||

| 300 | <8 | ||||||||||

| 3 | SL—U210/2—C | 12 | 200 | 90 | >8 | 4 | 7.6×3×3 | 18 | 7.5×8 | ||

| 250 | <8 | ||||||||||

| 4 | SL—U210/2—B | 9 | 150 | 90 | >8 | 3 | 5.8×3×2.3 | 13.5 | 7.5×6 | ||

| 200 | <8 | ||||||||||

| 5 | SL—U210/2—A | 6 | 120 | 85 | >8 | 2 | 4×3×1.6 | 9 | 7.5×4 | ||

| 150 | <8 | ||||||||||

| 6 | SL—U210/1.5—C | 9 | 150 | 90 | >8 | 4 | 7.6×2.5×3 | 14.4 | 5.5×8 | ||

| 200 | <8 | ||||||||||

| 7 | SL—U210/1.5—B | 6.75 | 100 | 90 | >8 | 3 | 5.8×2.5×2.3 | 10.8 | 5.5×6 | ||

| 130 | <8 | ||||||||||

| 8 | SL—U210/1.5—A | 4.5 | 60 | 85 | >8 | 2 | 4×2.5×1.6 | 7.2 | 5.5×4 |

0-8mm standard series of screen technical feature

| Item | Standard series |

Area (M2) |

Capacity (t/h) |

Efficiency (%) |

Feeding Size (mm) |

Feeding Moisture (%) |

Inclination angle of screen (Degree) |

Units (pcs) |

Dimension L×W×H (m) |

Weight (t) |

Motor Power (kW) |

| 1 | SL—U28/2.5—C | 15 | 250 | 90 | 0~200 | >8 | 0 | 4 | 7.6×3.5×3 | 22 | 11×8 |

| 300 | <8 | ||||||||||

| 2 | SL—U28/2.5—B | 11.25 | 200 | 90 | >8 | 3 | 5.8×3.5×2.3 | 16.5 | 11×6 | ||

| 250 | <8 | ||||||||||

| 3 | SL—U28/2—C | 12 | 200 | 90 | >8 | 4 | 7.6×3×3 | 18 | 7.5×8 | ||

| 250 | <8 | ||||||||||

| 4 | SL—U28/2—B | 9 | 120 | 90 | >8 | 3 | 5.8×3×2.3 | 13.5 | 7.5×6 | ||

| 200 | <8 | ||||||||||

| 5 | SL—U28/2—A | 6 | 100 | 85 | >8 | 2 | 4×3×1.6 | 9 | 7.5×4 | ||

| 130 | <8 | ||||||||||

| 6 | SL—U28/1.5—C | 9 | 120 | 90 | >8 | 4 | 7.6×2.5×3 | 14.4 | 5.5×8 | ||

| 150 | <8 | ||||||||||

| 7 | SL—U28/1.5—B | 6.75 | 80 | 90 | >8 | 3 | 5.8×2.5×2.3 | 10.8 | 5.5×6 | ||

| 100 | <8 | ||||||||||

| 8 | SL—U28/1.5—A | 4.5 | 50 | 85 | >8 | 2 | 4×2.5×1.6 | 7.2 | 5.5×4 |

Common used combined screen detailed technical features

| Item |

Main Technical Feature |

Screen Hole (mm) |

Unit |

Total Unit Number |

Capacity (t/h) |

Efficiency (%) |

Screen Area (M2) |

Feeding Moisture (%) |

Screen Inclination (Degree) |

Dimension L×W×H(m) |

Weight(t) |

Motor Power (kW) |

| 1 | 13 | 13 | 2 | 4 | ≤400 | 70 | 7.5 | No Limitation | 0 | 7.6×3.5×3 | 22 | 11×8 |

| SL—U2 25/2.5—C | 25 | 1 | 80 | 3.75 | ||||||||

| 50 | 50 | 1 | 80 | 3.75 | ||||||||

| 2 | 13 | 13 | 2 | 4 | ≤300 | 70 | 6 | 7.6×3×3 | 18 | 7.5×8 | ||

| SL—U225/2—C | 25 | 1 | 80 | 3 | ||||||||

| 50 | 50 | 1 | 80 | 3 | ||||||||

| 3 | 13 | 13 | 2 | 4 | ≤250 | 70 | 4.5 | 7.6×2.5×3 | 14.4 | 5.5×8 | ||

| SL—U2 25/1.5—C | 25 | 1 | 80 | 2.25 | ||||||||

| 50 | 50 | 1 | 80 | 2.25 | ||||||||

| 4 | 13 | 13 | 2 | 3 | ≤300 | 70 | 7.5 | 5.8×3.5×2.3 | 16.5 | 11×6 | ||

| SL—U2 25/2.5—B | 25 | 1 | 80 | 3.75 | ||||||||

| 5 | 13 | 13 | 2 | 3 | ≤250 | 70 | 6 | 5.8×3×2.3 | 13.5 | 7.5×6 | ||

| SL—U2 25 /2—B | 25 | 1 | 80 | 3 | ||||||||

| 6 | 13 | 13 | 2 | 3 | ≤200 | 70 | 4.5 | 5.8×2.5×2.3 | 10.8 | 5.5×6 | ||

| SL—U2 25/1.5—B | 25 | 1 | 80 | 2.25 | ||||||||

| 7 | 13 | 13 | 2 | 3 | ≤300 | 70 | 7.5 | 5.8×3.5×2.3 | 16.5 | 11×6 | ||

| SL—U250/2.5—B | 50 | 1 | 80 | 3.75 | ||||||||

| 8 | 13 | 13 | 2 | 3 | ≤250 | 70 | 6 | 5.8×3×2.3 | 13.5 | 7.5×6 | ||

| SL—U250/2—B | 50 | 1 | 80 | 3 | ||||||||

| 9 | 13 | 13 | 2 | 3 | ≤200 | 70 | 4.5 | 5.8×2.5×2.3 | 10.8 | 5.5×6 | ||

| SL—U2 50/1.5—B | 50 | 1 | 80 | 2.25 | ||||||||

| 10 | 25 | 25 | 2 | 3 | ≤450 | 85 | 7.5 | 5.8×3.5×2.3 | 16.5 | 11×6 | ||

| SL—U2 50/2.5—B | 50 | 1 | 83 | 3.75 | ||||||||

| 11 | 25 | 25 | 2 | 3 | ≤400 | 85 | 6 | 5.8×3×2.3 | 13.5 | 7.5×6 | ||

| SL—U2 50 /2—B | 50 | 1 | 83 | 3 | ||||||||

| 12 | 25 | 25 | 2 | 3 | ≤300 | 85 | 4.5 | 5.8×2.5×2.3 | 10.8 | 5.5×6 | ||

| SL—U2 50/1.5—B | 50 | 1 | 83 | 2.25 |

Note: 1. Any change of technical data will not inform additionally.