Product Center

Cone Crusher

Crushing Equipment

PE Jaw Crusher

PEW Jaw Crusher

CZC Jaw Crusher

PFW Impact Crusher

PF Impact Crusher

PFS Strong Impact Crusher

VSI Vertical Shaft Impact Crush

VSI5X High-Efficiency Impact Crusher

PC Hammer Crusher

PG Roller Crusher

Diesel Engine Crusher

PFL Vertical Compound Crusher

Crushing Plant

Auxiliary Equipment

GZD Vibrating Feeder

YZS Circular Vibrating Screen

SZF Linear Vibrating Screen

XSD Sand Washer

XL Sand Washer

XT Drum Stone Washer

Belt Conveyor

Grinding Equipment

High-Pressure Suspension Mill

MTW European Type Grinding Mill

CZM Ring Roller Micro Powder Mill

Raymond Mill

LM Vertical Mill

Ball Mill

Live Chat

Have question? Sales representatives

are available for live chat now.

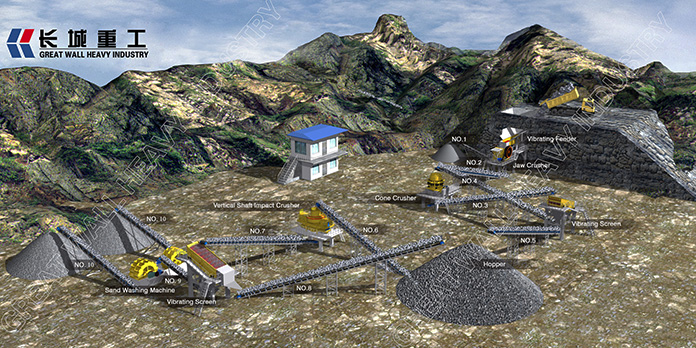

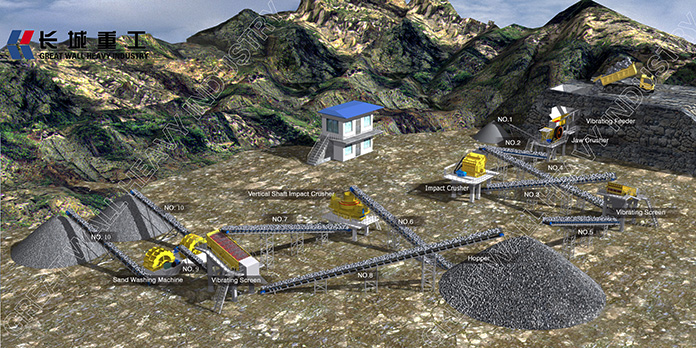

Sand Making Line

Sand making line consists of vibrating feeder, jaw crusher, cone crusher (or impact crusher), vertical shaft crusher (sand making machine), vibrating screen, sand washer, belt conveyor, electric control system, etc. Could crush materials such as limestone, granite, basalt, river stone, etc into sand used in construction. Designed capacity is 30-500 tph.

Tel: 0086-371-63769782

sales@greatwallcrusher.com

- Usage and Application

- Features

- Features

- Working Process

Sand making line consists of vibrating feeder, jaw crusher, cone crusher (or impact crusher), vertical shaft crusher (sand making machine), vibrating screen, sand washer, belt conveyor, electric control system, etc. Could crush materials such as limestone, granite, basalt, river stone, etc into sand used in construction. Designed capacity is 30-500 tph.

1. High production efficiency, low investment;

2. Easy in operation and convenient in usage;

3. Good grain shape for end products;

4. The sand can be screened into different grade and the size of sand is adjustable.

2. Easy in operation and convenient in usage;

3. Good grain shape for end products;

4. The sand can be screened into different grade and the size of sand is adjustable.

1. High production efficiency, low investment;

2. Easy in operation and convenient in usage;

3. Good grain shape for end products;

4. The sand can be screened into different grade and the size of sand is adjustable.

2. Easy in operation and convenient in usage;

3. Good grain shape for end products;

4. The sand can be screened into different grade and the size of sand is adjustable.

Large size stone is fed into silo by forklift, then transferred to jaw crusher for primary crushing by vibrating feeder below the silo, primary crushed stone would be transferred to cone crusher or impact crusher by belt conveyor for medium crushing, the crushed stone would be sent to the vibrating screen for screening by belt conveyor. Materials which can not meet the requirement sand making machine would return to cone crusher(Or impact crusher) by belt conveyor to be crushed again, materials which can meet the requirement of sand making machine would be fed into sand making machine for fine crushing process. Then finely crushed materials would be transferred to vibrating screen for screening, the large-particle stone material that does not meet the requirements shall be returned to the sand making machine by the belt conveyor for re-crushing, and the finished sand that meets the requirements of particle size shall enter the sand washing machine for cleaning, and the sand after cleaning shall be sent to the finished material pile by belt conveyor.

Note: Cone crusher is used as medium crushing equipment in sand making of high hardness materials, and impact crusher is used as medium crushing equipment in sand making of low hardness materials.

RELATED PRODUCTS