Product Center

GZD Vibrating Feeder

YZS Circular Vibrating Screen

SZF Linear Vibrating Screen

XSD Sand Washer

XL Sand Washer

XT Drum Stone Washer

Belt Conveyor

Have question? Sales representatives

are available for live chat now.

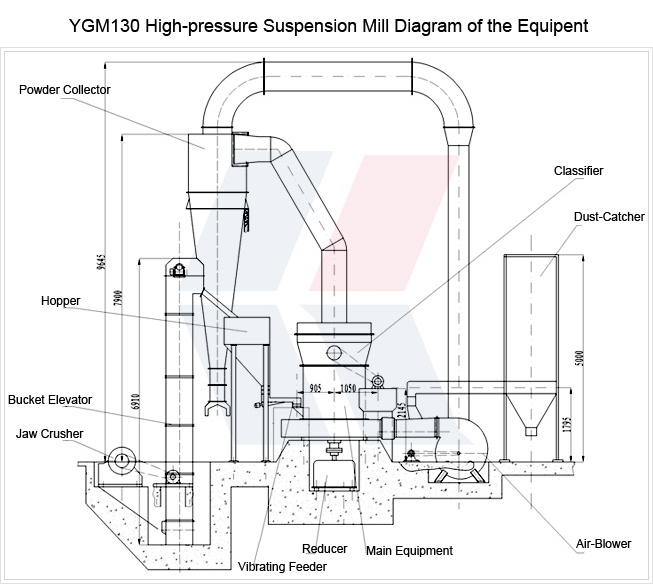

YGM Mill Production Line

High-Pressure Suspension Mill Production Line is mainly consisted of jaw crusher,bucket elevator, hopper, vibrating feeder,grinder, air blower, powder collector, dust catcher.

0086-371-63769782

sales@greatwallcrusher.com

- Usage and Application

- Working Principle

- Features

- Main Specifications

Note: 1. Any change of technical data will not inform additionally.